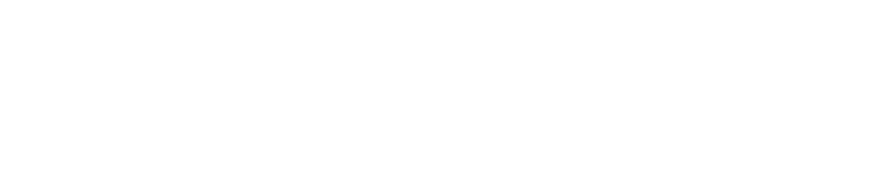

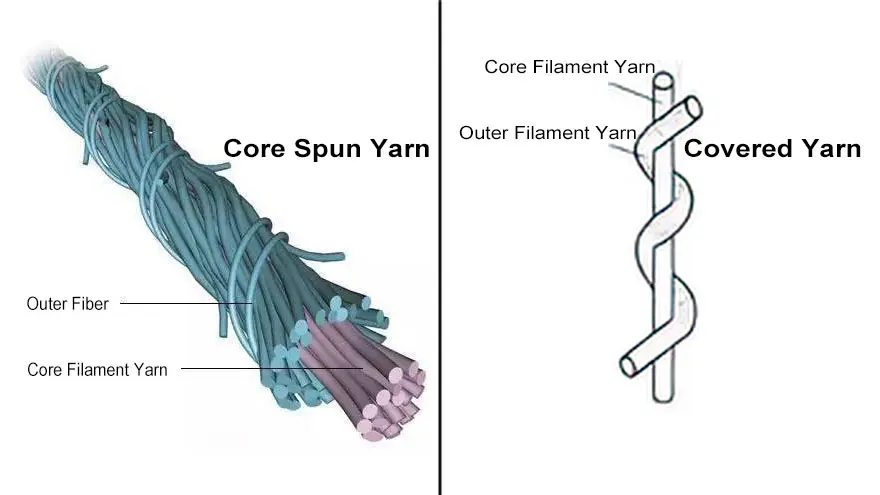

Yes, linen yarn can be made into core spun yarn. By using a strong continuous filament core (like polyester, nylon, or spandex) and wrapping it with linen fibers, we combine linen’s natural look and feel with added strength, durability, or stretch.

Core spun linen yarn has a continuous core—often polyester, nylon, or elastane—wrapped by linen fibers. This design keeps the natural texture and breathability of linen, while improving strength, stretch recovery, abrasion resistance, and seam performance. It is ideal for denim, workwear, home textiles, and high-end apparel where linen’s look is desired but with better durability.

Let’s go deeper into the features, processes, and uses of core spun linen yarn.

Advantages of core spun linen yarn

I use core spun linen yarn when I want linen’s natural character with enhanced performance.

Advantages include higher tensile strength, better abrasion resistance, improved seam life, reduced pilling, and optional stretch recovery. The core makes the yarn run smoother in weaving/knitting, while the linen sheath keeps the cool, crisp, and eco-friendly qualities that buyers love.

Key performance gains

- Strength: The core carries part of the load, reducing yarn breakage during weaving.

- Abrasion resistance: Useful for upholstery, denim, and uniforms.

- Stretch recovery: With spandex cores, garments keep their shape.

- Processing efficiency: Less fluff and breakage on high-speed looms.

- Moisture comfort: Linen sheath still wicks moisture well.

Example end uses:

| End Use | Core Material | Linen % | Benefit Focus |

|---|---|---|---|

| Denim | Spandex | 70% | Stretch + linen texture |

| Workwear | Polyester | 60% | Strength + breathability |

| Home textiles | Polyester/Nylon | 80% | Durable + natural look |

| Fashion knits | Spandex/Polyester | 65% | Comfort stretch + eco appeal |

What are the common spinning process for linen?

Linen spinning can be done in multiple ways depending on fiber length and quality.

Common processes include wet spinning for fine, smooth yarns; dry spinning for coarser yarns; semi-wet spinning as a cost-effective middle ground; and blending spinning for mixed fibers. For core spun linen, ring spinning and air-jet spinning are often used to wrap the core.

Spinning methods overview

- Wet spinning: Flax fibers are kept moist for maximum smoothness—best for high-end apparel linen.

- Dry spinning: Fibers spun without water—used for coarse yarns like ropes or heavy-duty fabrics.

- Semi-wet spinning: Partial moisture control—balances cost and smoothness.

- Blended spinning: Linen combined with cotton, viscose, or synthetics for improved softness or strength.

For core spun linen:

- Ring spinning: Wraps the linen sheath around the core with high precision.

- Air-jet spinning: Faster production but may create a slightly fuzzier surface.

| Process Type | Surface Quality | Speed | Typical Application |

|---|---|---|---|

| Wet spinning | Smoothest | Slower | Luxury linen fabrics |

| Dry spinning | Coarser | Medium | Rug, rope, heavy cloth |

| Ring spinning | Precision wrap | Medium | Core spun fashion/workwear |

| Air-jet | Slightly fuzzy | Faster | Knits, cost-effective blends |

What is the difference between core-spun linen yarn and regular linen yarn?

Both have linen on the outside, but their performance differs greatly.

Regular linen yarn is all-linen, offering natural coolness and breathability but lower stretch and seam strength. Core-spun linen yarn has a filament core for added strength, durability, or elasticity, while keeping linen’s surface feel and look.

Comparison points

- Structure:

- Regular linen: All staple linen fibers.

- Core spun linen: Continuous core + linen sheath.

- Strength: Core spun is stronger due to filament core.

- Stretch: Core spun with spandex core can stretch and recover; regular linen cannot.

- Durability: Core spun resists breakage during weaving and use.

- Cost: Core spun is slightly more expensive due to added core material and process.

| Feature | Regular Linen | Core Spun Linen |

|---|---|---|

| Breathability | Excellent | Excellent |

| Strength | Medium | High |

| Stretch | None | Optional (spandex) |

| Durability | Medium | High |

| Cost | Lower | Higher |

How to identify linen yarn?

I check both the fiber’s visual and physical traits.

Linen yarn has a slightly irregular texture, a natural luster, and feels cool to the touch. It wrinkles easily, absorbs moisture quickly, and shows a characteristic cross-section under a microscope with polygonal shapes.

Practical checks

- Look: Slight slubs and natural sheen.

- Touch: Crisp, cool, and firm.

- Water test: Absorbs water fast.

- Wrinkle test: Creases stay easily.

- Burn test: Smells like burning paper, leaves soft ash.

Microscopic view: Polygonal cross-sections with distinct nodes.

| Test Type | Expected Result for Linen |

|---|---|

| Visual | Slubs, natural sheen |

| Touch | Cool, crisp |

| Absorption | Fast soak |

| Wrinkle | Permanent creases |

| Burn | Paper smell, fine ash |

What are the four types of linen?

Linen is classified based on its weave or application.

The four main types are damask linen (patterned), plain-woven linen (smooth, lightweight), loosely woven linen (highly absorbent), and sheeting linen (heavy, durable). Each has unique uses in apparel or home textiles.

Linen types overview

- Damask linen: Jacquard-patterned, used for tablecloths and luxury apparel.

- Plain-woven linen: Smooth, used for summer shirts, dresses.

- Loosely woven linen: Soft and absorbent, used for towels.

- Sheeting linen: Heavyweight, used for trousers, upholstery.

| Linen Type | Weight | Main Use | Key Trait |

|---|---|---|---|

| Damask | Light–Med | Tableware, apparel | Patterned sheen |

| Plain-woven | Light | Dresses, shirts | Smooth surface |

| Loosely woven | Light | Towels, wipes | Absorbent |

| Sheeting | Heavy | Pants, bedding, upholstery | Durable, dense |

Conclusion

Core spun linen yarn gives me the beauty of linen and the strength of a filament core—perfect for brands wanting eco-style with better performance.